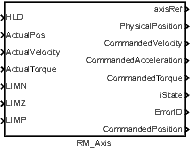

RM_Axis – Motion control axis

Block SymbolLicensing group: MOTION CONTROL

Function Description

The RM_AXIS block is a cornerstone of the motion control solution within the REXYGEN

system. This base block keeps all status values and implements basic algorithm for one motion

control axis (one motor), which includes limits checking, emergency stop, etc. The block is

used for both real and virtual axes. The real axis must have a position feedback controller,

which is out of this block’s scope. The key status values are commanded position, velocity,

acceleration and torque, as well as state of the axis, axis error code and a reference to the

block, which controls the axis.

This block (like all blocks in the motion control library) does not implement a feedback controller which would keep the actual position as near to the commanded position as possible. Such a controller must be provided by using other blocks (e.g. PIDU) or external (hardware) controller. The feedback signals are used for lag checking, homing and could be used in special motion control blocks.

The parameters of this block correspond with the requirements of the PLCopen standard for an axis. If improper parameters are set, the errorID output is set to -700 (invalid parameter) and all motion blocks fail with the -720 error code (general failure).

Note that the default values for position, velocity and acceleration limits are intentionally set to , which makes them invalid. Limits must always be set by the user according to the real axis and the axis actuator.

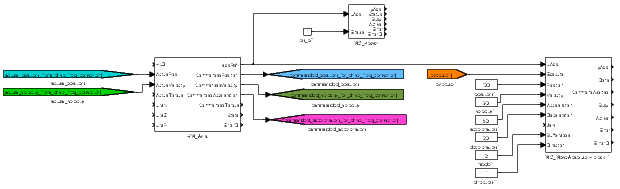

Example

Following example illustrates basic principle of use of motion control blocks. It presents the

minimal configuration which is needed for operation of a physical or virtual axis. The axis is

represented by RM_Axis block. The limitations imposed on the motion trajectory in form of

maximum velocity, acceleration, jerk and position have to be set in parameters of the RM_Axis

block. The inputs can be connected to supply the values of actual position, speed and torque

(feedback for slip monitoring) or logical limit switch signals for homing procedure. The

axisRef output signal needs to be connected to any motion control block related to the

corresponding axis. The axis has to be activated by enabling the MC_Power block. The state

of the axis changes from Disabled to Standstill (see the following state transition

diagram) and any discrete, continuous or synchronized motion can be started by

executing a proper functional block (e.g. MC_MoveAbsolute). The trajectory of motion in

form of desired position, velocity and acceleration is generated in output signals of

the RM_Axis block. The reference values are provided to an actuator control loop

which is implemented locally in REXYGEN system in the same or different task

or they are transmitted via a serial communication interface to end device which

controls the motor motion (servo amplifier, frequency inverter etc.). In case of any

error, the axis performs an emergency stop and indicates the error ID. The error has

to be confirmed by executing the MC_Reset block prior to any subsequent motion

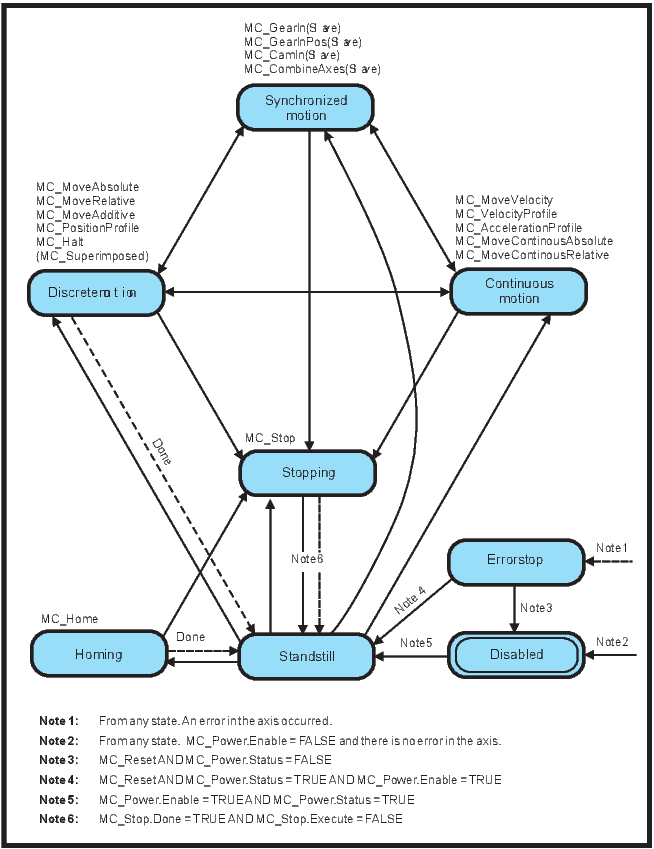

command. The following state diagram demonstrates the state transitions of an

axis.

Axis state transition diagram

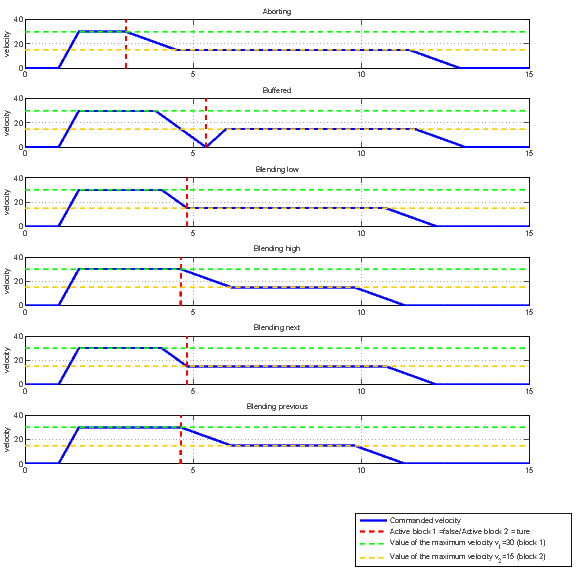

Motion blending

According to PLCOpen specification, number of motion control blocks allow to specify

BufferMode parameter, which determines a behaviour of the axis in case that a motion

command is interrupted by another one before the first motion is finished. This transition from

one motion to another (called "Blending") can be handled in various ways. The following table

presents a brief explanation of functionality of each blending mode and the resulting shapes of

generated trajectories are illustrated in the figure. For detailed description see full PLCOpen

specification.

| Aborting | The new motion is executed immediately |

| Buffered | the new motion is executed immediately after finishing the previous one, there is no blending |

| Blending low | the new motion is executed immediately after finishing the previous one, but the axis will not stop between the movements, the first motion ends with the lower limit for maximum velocity of both blocks at the first end-position |

| Blending high | the new motion is executed immediately after finishing the previous one, but the axis will not stop between the movements, the first motion ends with the higher limit for maximum velocity of both blocks at the first end-position |

| Blending previous | the new motion is executed immediately after finishing the previous one, but the axis will not stop between the movements, the first motion ends with the limit for maximum velocity of first block at the first end-position |

| Blending next | the new motion is executed immediately after finishing the previous one, but the axis will not stop between the movements, the first motion ends with the limit for maximum velocity of second block at the first end-position |

Illustration of blending modes

[Back to top] [Up] [Next]

2020 © REX Controls s.r.o., www.rexygen.com